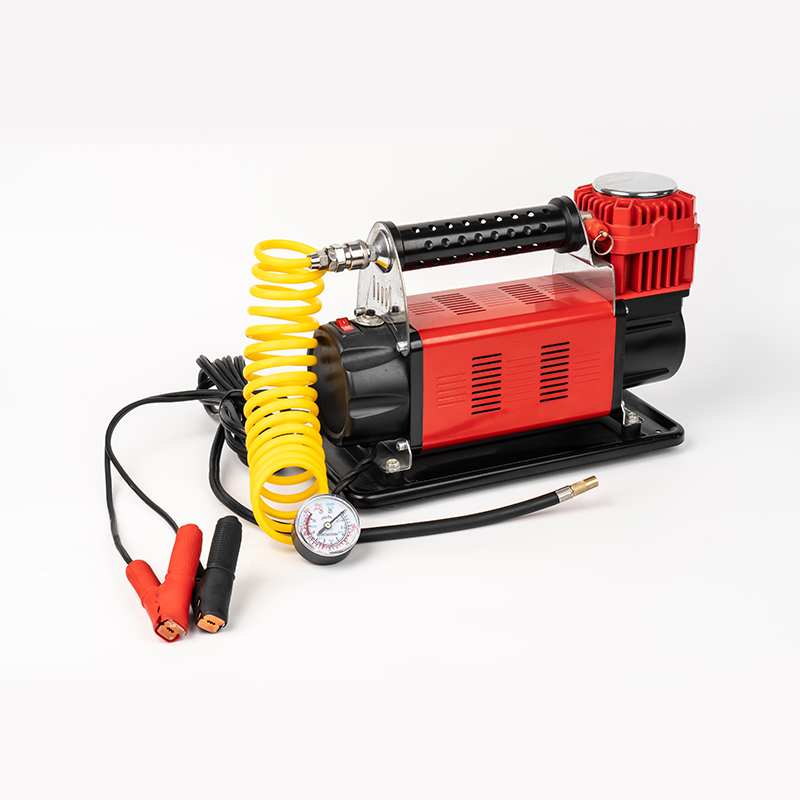

The dual ventilation design of the Double cylinder air compressor with highlight LED means that the air compressor has more heat dissipation channels and can more effectively dissipate the heat generated inside the machine to the external environment. Good heat dissipation performance is the key to maintaining efficient operation of the air compressor, because high temperatures will cause increased thermal stress on the internal components of the machine, thereby affecting its working efficiency and lifespan. Through the double ventilation design, the air compressor can maintain a lower operating temperature during continuous operation, thereby reducing performance degradation caused by high temperatures and improving work efficiency.

Due to the improved heat dissipation performance, the air compressor with dual ventilation design can significantly reduce the risk of shutdown due to overheating. This advantage is especially obvious when working in high temperature environments or for long periods of time. Less downtime means more work time and greater productivity.

The dual ventilation design also helps optimize the airflow distribution inside the air compressor to ensure that each component can be fully cooled. This helps reduce performance bottlenecks caused by local overheating and makes the overall air compressor work more coordinated and efficient.

The dual-vent design significantly extends the life of the compressor's internal components by lowering operating temperatures and reducing overheating shutdowns. This includes key components such as motors, cylinders, and pistons. Their stable operation is the basis for ensuring the overall stability of the air compressor.

High temperature and poor heat dissipation are one of the main causes of air compressor failure. The dual ventilation design reduces the risk of failure caused by high temperatures by improving heat dissipation performance, thereby improving the overall stability of the air compressor. This means that users can use the air compressor to work more reliably and reduce losses and inconvenience caused by failures.

Good heat dissipation and airflow distribution also help improve the smooth operation of the air compressor. In the case of high temperature or large load changes, the double ventilation design can adjust the internal temperature of the machine more quickly, reduce performance fluctuations caused by temperature changes, and keep the air compressor in a stable operating state.

The dual ventilation design of the Double cylinder air compressor with highlight LED plays an important role in improving work efficiency and stability. By enhancing heat dissipation performance, reducing overheating shutdowns, optimizing air flow distribution and other measures, the dual ventilation design ensures that the air compressor can maintain efficient and stable operation in high temperature environments or when working continuously for a long time.

English

English Español

Español عربى

عربى Türk

Türk