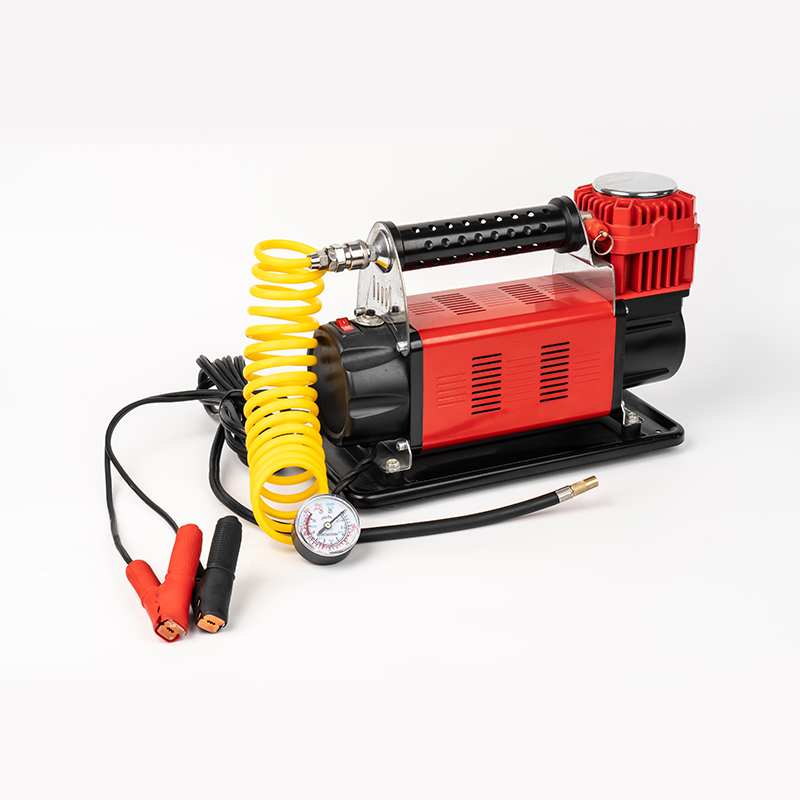

In car travel, the Automotive Tire Inflator is a key device to ensure driving safety. However, when facing harsh environments, such as hot deserts, cold polar regions, humid rainforests or wilderness ravaged by sand and dust, how to ensure that it can work properly?

First of all, in terms of component protection, high-quality protective coatings should be used. Whether it is a motor, circuit or air path component, a special protective coating is like a layer of solid armor. In high temperature environments, this coating can effectively reflect heat and prevent the performance of components from being degraded or damaged due to overheating. For example, ceramic-based protective coatings, which can withstand extremely high temperatures, ensure that the internal components of the inflator remain stable in the desert under the scorching sun. In humid environments, protective coatings can prevent erosion by water vapor and avoid rust and short circuit problems. For environments with more sand and dust, the smooth surface of the coating can reduce the adhesion of sand and dust and maintain the normal heat dissipation and operation of the components.

Secondly, the sealing design is crucial. An excellent automotive tire inflator should have a multi-layer sealing structure. At the air inlet and outlet, highly elastic and wear-resistant rubber seals are used, which can not only ensure the effective transmission of gas, but also prevent the entry of sand, dust and moisture. At the joints of the fuselage, sealants are used for filling to ensure that the entire air pump forms a relatively closed environment. At the same time, for parts such as buttons and display screens, there should also be special sealing designs, such as silicone sealing gaskets, so that these vulnerable parts are properly protected.

Furthermore, the stability of the circuit system is the key. In harsh environments, voltage fluctuations are a common problem. Therefore, the circuit of the air pump should be equipped with an intelligent voltage regulation module. When the voltage is too high or too low, the module can automatically adjust the voltage to ensure that the motor and other electronic components work within the normal voltage range. In addition, the wiring of the circuit should be reasonable and compact to reduce the risk of loose lines caused by bumps. At the same time, anti-interference capacitors and inductors are added to enhance the circuit's anti-electromagnetic interference ability, so that the air pump can also operate accurately in a complex electromagnetic environment.

In addition, for the power source, if it is an electric air pump, the selection and management of the battery cannot be ignored. Choose lithium batteries with wide temperature characteristics. This type of battery can still maintain good discharge performance at low temperatures and has stable chemical properties at high temperatures. In addition, the built-in battery management system should be able to accurately monitor the charge and discharge status of the battery to prevent overcharging, over-discharging and overheating. If the air pump is powered by the car cigarette lighter, its plug and connecting wire should have good conductivity and anti-bending ability to ensure continuous and stable power supply during vehicle driving.

In order to adapt to harsh environments, the overall structure of the air pump can also be reinforced. Use high-strength engineering plastics or metal shells to enhance its impact resistance. In terms of design, make the internal components layout reasonable to reduce the risk of damage caused by bumps and collisions. Through these comprehensive measures, we can ensure that the car tire air pump can be like a reliable partner in any harsh environment, escorting your driving safety at any time, so that you can travel without worries.

English

English Español

Español عربى

عربى Türk

Türk